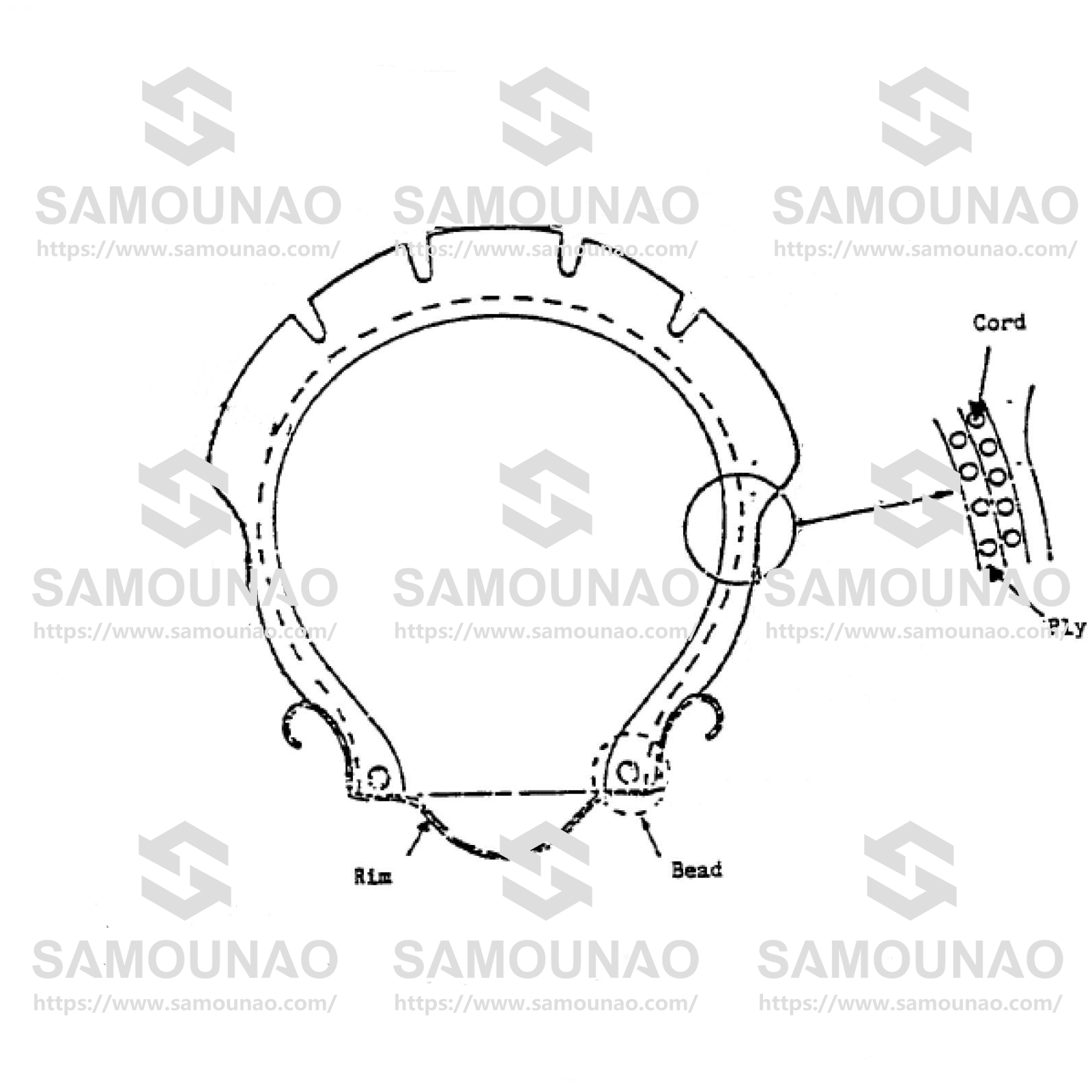

The most popular bicycle inner tubes and motorcycle inner tubes are made from butyl rubber, which is a synthetic elastomer made by combining isobutylene and isoprene. This material is an excellent opinion for inner tubes, as it show quite positive shock absorption characteristics & durability, while keep low moisture and gas permeability, to maintain internal pressure at least 3~6 month or more. it is better than nature tubes on this factor .

On the cost ,our butyl tube is almost same with nature tubes due to new technology and rubber formular is introduced

Butyl inner tubes are known for their classic black color, durability, and low cost & gas permeability , which provide an effective solution for a large population of users.

For these reasons, butyl tubes are widely used commercially. For example, these are most likely the tubes on your new bike, or that a shop may use to replace old tire. In the event of a puncture, butyl tubes are easy to patch using an inexpensive patch kit, which is readily available at bike shops, as well as most hardware stores. These patches are applied using rubber cement, and have a similar elasticity to the tube itself, ensuring a positive repair.